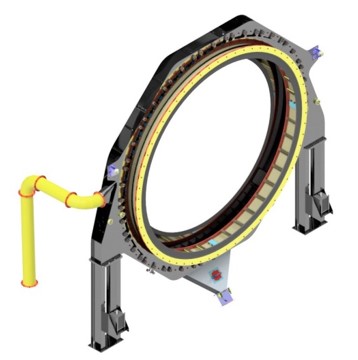

Our graphite seals reduce false air intake and allow enough flexibility to follow the kiln’s movements. Rows of graphite blocks held in place by a wire rope system. This, ensures an efficient seal against the outer air casing.

The inlet and outlet zones with seals are very critical parts of kiln. If false air enters the kiln system, fuel consumption increases, production output decrease and operating expenses go up. Graphite seals require no greasing and are practically maintenance – free under normal operating conditions.

Main advantages:

- Provide effective leak tightness around the kiln discharge hood to prevent cold air

- Ingress or release of hot gases and particles,

- Improve pressure stability in the kiln

- Allow installation on existing kilns without modifying the kiln shell or kiln inlet

- Absorption of kiln expansion and slide range

- No maintenance

Kiln Dimension (m) |

|||||||

|---|---|---|---|---|---|---|---|

| Ø3,55 | Ø3,8 | Ø4 | Ø4,2 | Ø4,5 | Ø4,6 | Ø4,8 | Ø5,2 |